You likely know what MCC stands for if you are an electrical engineer. Therefore, I would like to briefly introduce it to those who may not be familiar with it.

The MCC stands for “Motor Control Center,” As you can guess from its name, it is used to control motors in industrial or commercial applications involving many motors. This guide is all about MCC panel.

What is an MCC panel?

In motors, electrical energy is used to perform mechanical operations such as rotating a pump, fan, blower, etc. Industrial development has increased the need for automation and mechanization of the various industrial processes. The mechanization of different industrial processes requires a lot of motors, so to control all of these motors, MCCs are needed.

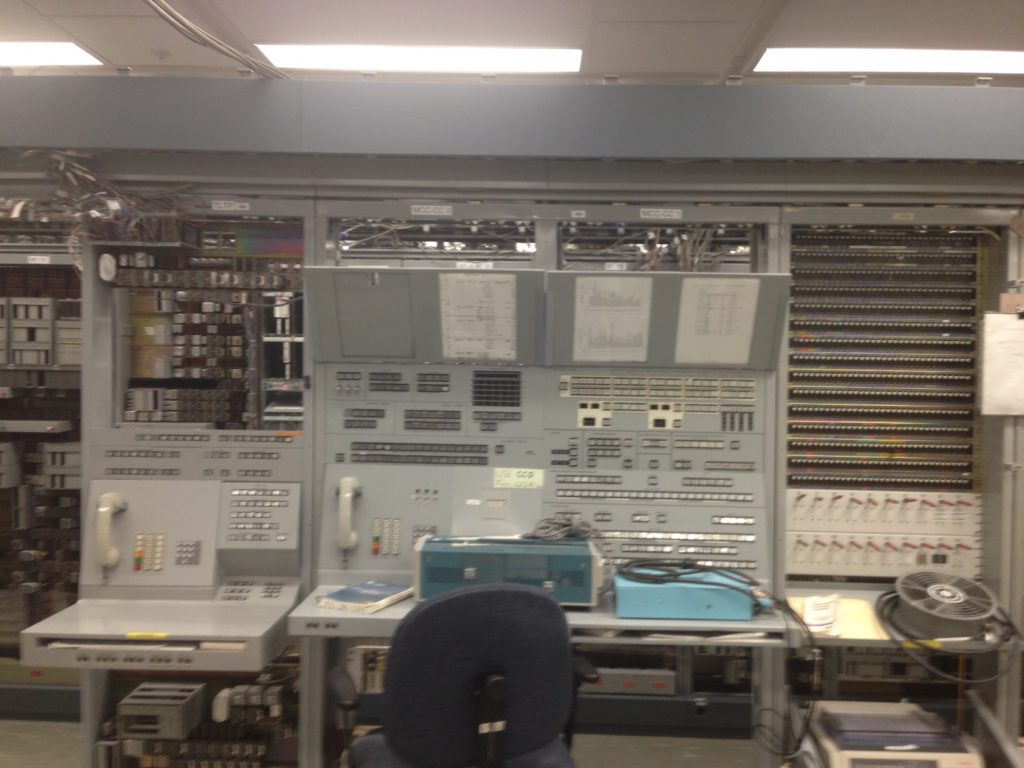

As you can see in the image below, the MCC is an enormous enclosure that would house all of the motor control equipment.

There is no need for wiring since the MCC can plug in the control components. These components can be plugged in or unplugged, and thus no wiring is necessary. There would be an MCC, which would be constructed out of a bus bar and other components that would allow the motor to be controlled and the components to be arranged in an integrated panel. In addition to the MCC, there are different ways to start motors, including the DOL and star-delta starters.

Components in an MCC panel

As discussed above, MCCs can control multiple motor operations since they are composed of several components, including a motor starter, bus bar, control equipment, etc. All of these components are used to control the electric motor. They are mounted in a panel consisting of a mixture of iron metal and carbon iron.

1. The Bus bar

Generally speaking, a bus bar is a bar that is made up of brass, copper, etc. and is used primarily to provide or distribute power to electrical equipment. Therefore, the bus bar will serve as a power distributor in an MCC. Using a bus bar in an MCC has the significant advantage of eliminating the need for wiring of many components, which reduces both the size and the number of parts in the MCC. The electrical equipment in an MCC can be easily connected with the help of a bus bar, which could also help locate the error. A bus bar can be easily used to troubleshoot problems in an MCC.

Read more:The top 5 ways to overcome IT challenges

2. The Overload relays

Overheating of the motor can be caused by overloading the driving machinery. These relays would further protect the motor from overheating. This can also occur when there is a low voltage level or if there is an open phase in a three-phase system. Overload relays will open when an excessive current is drawn for a defined time, and the motor will be disconnected from the power source. Using the relay would allow the temporary overload to occur without causing any damage to the motor while blocking the over-load that could damage it.

3. The miniature circuit breaker

An MCB is designed to disconnect a circuit when a circuit has an excessive current flow or when a circuit has an electrical load that exceeds its capacity.

4. Control Transformers

It may be necessary to operate the control circuit at a lower voltage than the power circuit. We can use a control transformer to reduce the voltage in this case.

5. The Magnetic contactors

A magnetic contactor is used to start or stop a motor in an MCC. Usually, a remote control device will be used to start and stop the motor, and for this purpose, we can use a contractor. For the magnetic contactor to work, it must operate by electromagnetic principles.

6. The Time delay relay

A time delay relay is primarily used to provide on-delay and off-delay timing. This device can therefore be used for the automatic time setting, and this device can be combined with the other control equipment in an MCC, such as a magnetic contactor.

7. The Limit switch

When a specified limit is reached, such as if there is an excess overload, this component emits a signal. For example, the machine’s rotation speed, the position of a machine part, etc., could be the limit. This device can replace a human operator and be used in situations where it is not possible to use a human operator.

Purpose of an MCC panel

1. Motor starts

The start-up of a motor is a necessary process, and it should be slow and gradual to protect the machine. Some industrial machines might suffer damage if they’re operated too fast initially instead of gradually increasing their speed.

2. Operational control.

Make sure this device maintains the appropriate operating speed and characteristics. Therefore, the motor, machine, materials, and operator are protected by controlling or maintaining the operational speed.

3. Stopping

The MCC must be capable of providing fast stopping of the motor because the machine must be stopped very quickly in certain situations and the MCC should do this. For specific industrial machinery, emergency stops must be implemented.

4. Reversing

The direction of machine rotation would need to be changed in an industrial process, which should be done quickly. The direction of machine rotation would need to be changed continuously in an industrial process.

5. Damage prevention

Keeping the machine safe from damage is essential, as it can be costly to repair. An example would be preventing the pileups in a conveyor with a machine. The machine must perform the necessary operations to reverse, stop, or slow. The MCC must control the machine by the process.

Considerations that must be taken while installing an MCC panel

- It is essential to determine whether the power is AC or DC in electrical service. We should consider the frequency, several phases, and voltage if it is AC.

- The motor must be connected to the electrical service and sized appropriately for the machine load if the power rating is HP. The speed and torque of the motor must also be considered.

- The motor controller should be able to start, stop, or reverse the motor operation according to the requirements.

- It must be placed where it will not be affected by certain environmental conditions such as rain, snow, dirt, oils, or lubricants.

Conclusion

After reading this article, it is concluded that MCC can convert electrical energy to mechanical energy. It is one of the essential parts of the motor. The purpose of the MCC is to start the engine gradually Instead of starting at high speed to decrease motor damage. It can also prevent the motor from overloading.